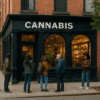

Cannabis producers across the Northeast have been navigating a wave of fresh traceability mandates in recent years. Several states including New York, New Jersey, and Massachusetts have introduced revised rules that require more detailed tracking of cannabis plants and their derivatives throughout the supply chain. These regulations are intended to combat diversion, enhance product safety, and comply with federal expectations on monitoring controlled substances. What has emerged is an industry in adjustment, reshaping operations and sometimes struggling to adapt to additional administrative burdens and technical demands.

Farmers and processors meet the data challenge

Traceability is hardly a new concept for cannabis, but recent changes deepen expectations at every step, from seed or clone to retail sale. Many producers report needing to overhaul their record-keeping, often moving from manual systems or basic software to integrated platforms. Larger facilities have embraced commercial seed-to-sale software such as Metrc or BioTrack, which provide a centralized database to track exactly where every plant and product batch is at any moment. Small growers, however, often face steeper hurdles, both financial and technical.

This digital shift includes scanning barcodes on plants during every critical event: transplanting, pruning, pesticide application, harvesting, and processing. Some operators speak of dedicating staff just to compliance monitoring, a task that pulls them away from direct cultivation or production work. The new burden can spark tension between maintaining efficient operations and meeting regulatory timelines and data accuracy standards.

The requirement to report every sample tested in state-licensed labs has also introduced complexities. Labs must interface smoothly with producer data systems so results flow back accurately. Mismatched data or delays can hold up shipments or risk compliance violations, creating a ripple effect that touches supply chain schedules and product availability.

The ripple effect on cultivation practices

These tighter traceability rules push producers to think carefully about their planting schedules, crop separation, and inventory counts. Many cultivators separate plants into smaller lots or batches to avoid confusion during harvest tracking. While this can increase data clarity, it raises operational costs and complicates canopy management. For some, the added workload persuades them to scale back rather than expand.

Furthermore, the focus on detailed event tracking naturally shines a spotlight on pest and nutrient management. Regulators want to see a clear record of every input, linked directly to specific plants or batches. This level of scrutiny encourages more precise use of additives and pesticides. Some growers describe how the data demands push them to adopt cleaner, more consistent methods not just for compliance but for long-term product quality.

On the processing side, manufacturers have had to rethink workflows to assure every batch of edibles, concentrates, or infused products can be reliably traced back. Unit-level tracking means that product packaging often includes QR codes or unique identifiers that link back to inventory and testing data. This has prompted investments in new packaging lines and software solutions.

State-level differences shape diverse responses

The Northeast contains a patchwork of regulatory approaches. New York’s Office of Cannabis Management has implemented extensive reporting rules with a highly digital infrastructure, expecting producers to use the state’s integrated system. In New Jersey, the Cannabis Regulatory Commission similarly emphasizes real-time data entry and laboratory integration, but smaller licensees sometimes report greater challenges accessing or affording required technology.

Massachusetts introduced early traceability systems and has gained lessons that other states now appear to consider. Its regulations require comprehensive tracking but have also pushed for more education and support for producers making the transition. This includes outreach programs highlighting how compliant traceability can reduce product recalls or enforcement issues.

Meanwhile, other states in the Northeast region weigh the balance between strict traceability and industry growth. Some propose phased implementations or tiered requirements based on producer size to temper the impact on smaller cultivators.

Looking at the broader industry implications

Beyond the immediate operational shifts, introducing robust traceability rules feeds into larger questions about the cannabis industry’s future identity and relationship with regulators. Producers generally recognize that clear, transparent supply chains help legitimize the business and build consumer trust. At the same time, the accompanying costs and complexity sometimes fuel frustration with state processes.

The Northeast’s market still feels in many ways emergent, with legalization unfolding unevenly and commercial activity growing at varied paces across states. Traceability can become a touchstone metric for how the industry matures. As states observe compliance outcomes, some rules may evolve, potentially offering more flexibility or integrating new technology such as RFID tracking or blockchain for immutable records.

For now, though, the region’s cannabis producers are grinding through the requirements, often learning how to blend cultivation savvy with compliance expertise. This intersection seems likely to shape not only operational norms but also who thrives in the increasingly regulated legal market.

Understanding these shifts offers a window on the challenges and adaptations of cannabis production in a heavily regulated environment. What stands out is how traceability demands reverberate far beyond paperwork, influencing planting choices, labor allocation, and even product innovation. For those watching the Northeast, these adjustments are part of a broad narrative about cannabis legalization as a real-world industry-not just a recreational or medical novelty.

While the state-mandated requirements continue to settle in, it will be interesting to keep track of further innovations and responses as producers and regulators find their mutual footing in this complex landscape.

For more insight into the evolving cannabis landscape in the Northeast, the New York Office of Cannabis Management offers in-depth resources and guidance on regulatory compliance. Meanwhile, New Jersey Cannabis Regulatory Commission provides updates and support aimed at helping businesses meet the state’s tracking standards. To explore broader trends and technical developments, Massachusetts Cannabis Control Commission publishes publicly accessible compliance materials and educational programs.

At the intersection of cultivation and compliance, these evolving traceability rules portray a cannabis industry actively learning how to function within the framework of legal oversight, sometimes awkwardly but with an eye on establishing lasting, normalized business practices.

Sources and Helpful Links

- New York Office of Cannabis Management, official site with regulatory details and compliance info.

- New Jersey Cannabis Regulatory Commission, updates on licensing, traceability, and market entry.

- Massachusetts Cannabis Control Commission, resources about regulations and industry support.

- Metrc, one of the leading seed-to-sale tracking software providers widely used in the cannabis industry.