Indoor cannabis cultivation has long been a resource-heavy endeavor, relying on precise control over light, temperature, and humidity to coax the best yields and quality from plants. With recent surges in energy prices across many regions, the economics that underlie these operations are facing fresh scrutiny. Growers, whether commercial or personal, are caught between maintaining established cultivation practices and adapting to costs that could quickly outpace profits or personal budgets.

Lighting Choices Meet a Changing Cost Landscape

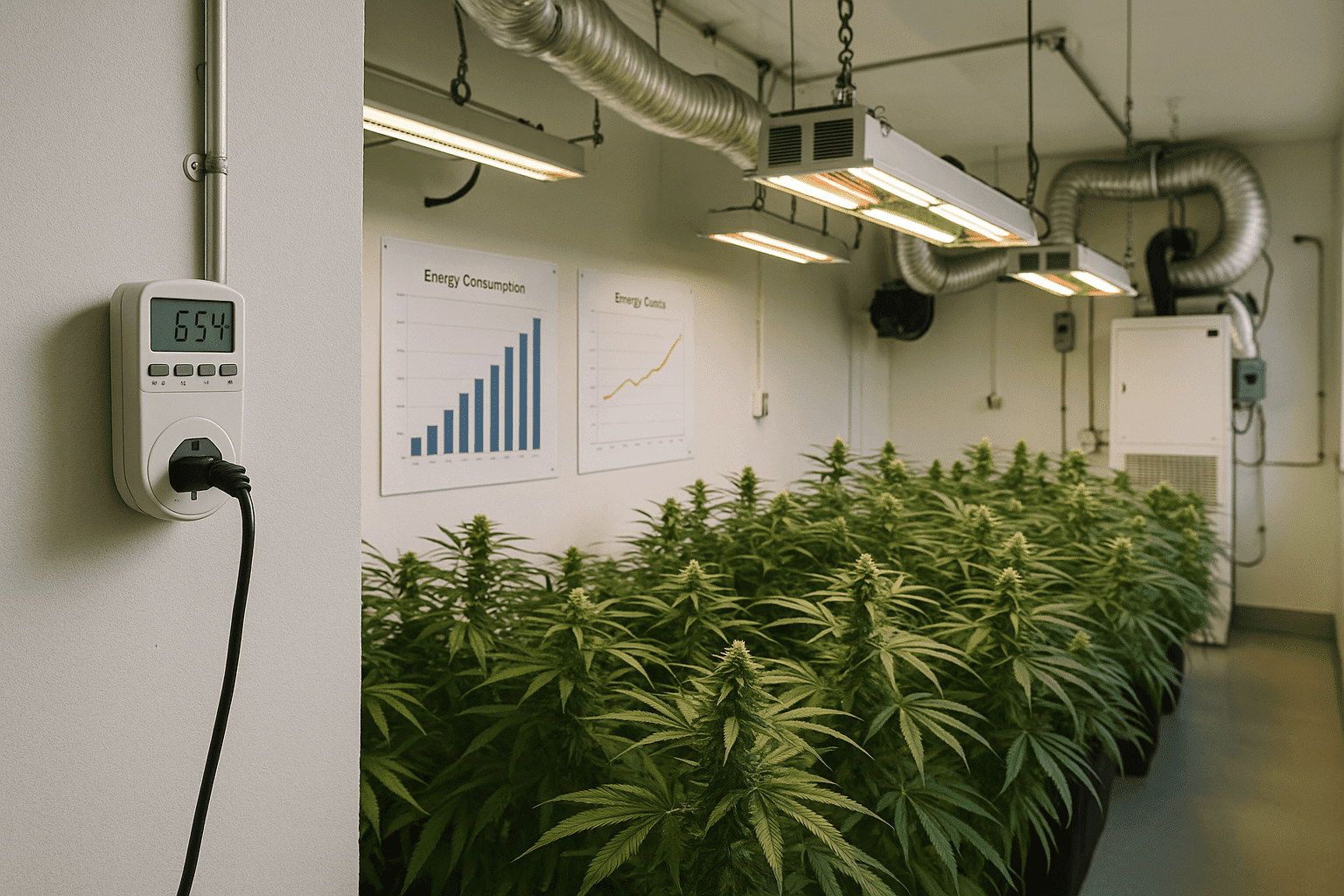

Lighting is often cited as the single largest energy consumer in indoor cannabis grows. Traditional setups have leaned heavily on high-intensity discharge lamps like metal halide or high-pressure sodium bulbs, prized for their proven results but also known for high electricity demands. As rates climb, cultivators are revisiting the balance between light intensity, spectrum, and the sheer number of hours lights run daily.

The advent of light-emitting diode (LED) technologies has been a notable development leading up to the current cost environment. LEDs tend to offer greater energy efficiency and customizable spectrums, but the initial investment has typically been higher. With energy expenses becoming a more immediate concern, some facilities and clever home growers are ramping up LED adoption. While the upfront sticker shock remains real, over time LEDs can reduce energy bills and heat output, easing air conditioning loads and improving environmental control. This has been documented in case studies from the U.S. Department of Energy’s AmeriLED program, which highlights long-term savings from LED retrofit projects in horticulture.

Still, not every grower can pivot technology overnight. Many rely on legacy equipment or are limited by facility design and capital availability. There is also ongoing debate over whether full-spectrum or partial-spectrum LED solutions equal the traditional HID outputs in final plant quality and yield. The tension between quick cost reductions and maintaining crop standards is palpable.

Ventilation and Climate Control Under Financial Pressure

Beyond lighting, the ventilation and climate systems in indoor grows are substantial energy consumers. Controlling temperature and humidity often means running air conditioners, dehumidifiers, fans, and filters at high capacity. Particularly in warmer climates or sealed environments, these can add significant demand onto an electrical grid.

As bills rise, some indoor growers are increasingly experimenting with shifting their operation hours. Running some climate control equipment only during off-peak hours, or optimizing cycles for ventilation with strategically located intake and exhaust fans, are ways participants attempt to trim spikes in power use. Yet these adjustments can only stretch so far without risking plant stress from too much temperature or humidity variation.

Others are looking toward passive climate techniques where architecture and grow layout play a more active role. Incorporating insulated walls, reflective surfaces, or even subterranean growing rooms takes cues from broader sustainable agriculture practices. Such retrofits are not trivial and generally demand larger investments or suitable existing infrastructure, but they promise longer-term relief from volatility in energy expenses.

Facility Decisions Reflect a Growing Divide

The cost issue also colors the debate around scale and location. Smaller home growers might accept compromises on yield or stretch their current infrastructure, but commercial operations with tight margins feel heavier pressure to make costly upgrades or rethink their business models. The rise in energy costs has fueled interest in outdoor or greenhouse cultivation as alternatives. These approaches leverage natural sunlight and airflow, which can dramatically cut electrical demand if local weather and seasonal conditions cooperate.

However, outdoor grows come with their own challenges – from pest management to security – and may not be feasible in all legal or environmental situations. Greenhouse setups represent a hybrid where supplemental lighting is reduced but not eliminated, sometimes incorporating solar panels or other renewable energy sources to offset consumption.

Industry voices have noted that energy price fluctuations highlight the advantages of flexible models that can switch between growing indoors and outdoors or alternate equipment usage. This kind of agility could be key to navigating continued uncertainty in utility markets along with any evolving regulations around cannabis production.

Energy Efficiency as a Competitive Edge

As energy expenses become a line item impossible to ignore, they are reshaping not just plant-level choices but the entire business ecology. Some operators are aggressively pursuing energy audits to identify underperforming equipment and inefficient scheduling.

Investment in automation, better sensors, and smart systems that adjust lighting and climate controls dynamically may pay off by minimizing waste. This aligns with broader trends in agricultural technology toward data-driven cultivation. While these systems represent additional upfront costs, they promise to extract every kilowatt-hour’s value in service of healthier plants.

At the same time, regional variations in electricity pricing and grid stability have sparked localized experimentation with backup generators, battery storage, and even microgrid configuration. These approaches seek to provide reliability as well as cost control in a market where outages or peak demand pricing can seriously disrupt sensitive crops.

Some commercial cultivators have reported direct savings and improved harvest consistency after installing modern LED lighting paired with improved air circulation equipment. The trick is balancing the immediate capital expense against unpredictability in energy pricing and evolving regulations.

The Human Side of Energy Pressures

Behind the technical and economic shifts, it is clear that rising energy costs impact growers on a deeply practical level. For smaller-scale and home cultivators, budgets may shrink, leading to choices around how much to grow, when to flower, or what genetics are sustainable to maintain under current resource costs.

Commercial businesses face strategic questions about pricing products higher to cover expenses or absorbing costs to remain competitive, possibly affecting employee wages and overall industry health. These ripple effects remind us that what seems like an abstract cost increase connects directly to people’s livelihoods and communities centered around cannabis.

The evolving landscape is shaping an environment that values energy-smart cultivation more than ever, pushing the community to innovate in how cannabis grows are powered and managed. Whether through technology upgrades, architectural redesigns, or new growing methods, the story unfolding around energy prices is now deeply woven into the fabric of cannabis cultivation itself.

Solutions will likely keep emerging from experimentation on many fronts as growers adapt to this fundamental cost pressure, among other challenges facing the industry today.

For those looking to learn more about energy use in cannabis growing and emerging strategies, resources such as the USDA Natural Resources Conservation Service and reports from Cannabis Business Times offer detailed perspectives and ongoing coverage.

Sources and Helpful Links

- U.S. Department of Energy AmeriLED program, highlighting energy savings from LED horticulture lighting.

- Hort Americas Lighting Efficiency, focusing on LED and air circulation improvements for cannabis growers.

- USDA Natural Resources Conservation Service, resources on sustainable agricultural practices.

- Cannabis Business Times Energy Usage, an ongoing report on cannabis cultivation energy consumption.