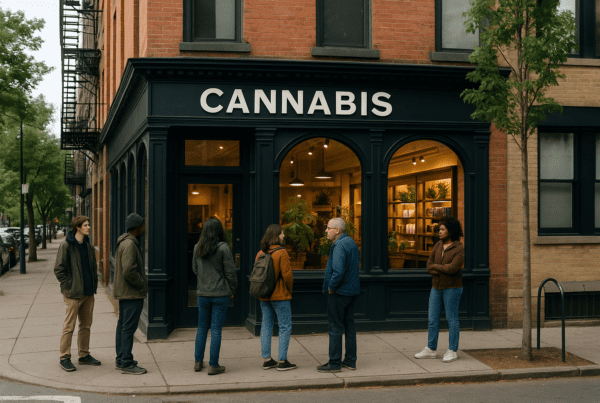

Recent updates in worker safety regulations have started to cast a new light on the daily realities inside cannabis cultivation facilities. These changes, while part of a broader trend toward formalizing standards in the cannabis industry, are proving to be more than just bureaucratic red tape. For growers and employees, they touch everything from how the workplace is organized to what protective gear is standard and how environmental factors like air quality are managed.

How safety measures frame the workday

Observing a cannabis cultivation facility today, it becomes clear that worker safety is not only about accident prevention but also about cultivating an environment where people can perform their tasks sustainably. Facilities are increasingly expected to address hazards related to chemical handling, repetitive motion, and respiratory risks. These often-overlooked factors accumulate daily and affect employees’ long-term health and performance.

For example, regulations are setting limits on exposure to pesticides and fertilizers used in cannabis growing, an area where protective protocols were once spotty or informal. This formal recognition of chemical hazards is leading facilities to implement clearer labeling, mandatory training, and better ventilation systems. The California Division of Occupational Safety and Health (Cal/OSHA) has been among those emphasizing these changes, with guidance tailored to the unique risks in cannabis operations that go beyond traditional agriculture.

Besides chemical safety, ergonomics and manual labor concerns have drawn attention. Cannabis cultivation involves repetitive activities like trimming and planting that can cause strain injuries. New rules encourage frequent breaks and ergonomic assessments to reduce these risks, which can often be ignored in fast-paced environments pushing for high yields.

Environmental controls are coming into sharper focus

The indoor nature of most commercial cannabis grows means that environmental controls remain critical for worker safety. Regulations now push for more rigorous air quality monitoring and management practices. Since mold, mildew, and airborne particulates can impact both plants and people, facilities have started investing in upgraded filtration and humidity control systems.

Although not all states have fully implemented these requirements, the trend signals a broader shift toward recognizing indoor air quality’s role in occupational health. The U.S. Occupational Safety and Health Administration (OSHA) has released general guidance supporting clean air initiatives that companies in emerging markets like cannabis can adapt to their specific settings.

Light exposure is another variable under scrutiny. Workers spend long hours under intense LED or high-pressure sodium lights, which affect comfort and eyesight. New protocols sometimes include recommendations on exposure time or protective eyewear, adding a layer of care not formerly standard in all operations.

Training and reporting as pillars of a safer workplace

Beyond physical changes, recent regulations emphasize education and transparency. Cultivation facilities increasingly adopt comprehensive training programs that cover everything from hazard recognition to proper equipment use. These programs respond to an industry that has grown faster than its regulatory frameworks, helping workers navigate both familiar and novel risks.

Reporting mechanisms are also evolving. Employees are encouraged or required to report injuries and unsafe conditions without fear of reprisal, fostering a stronger safety culture. Digital platforms and internal safety protocols help track concerns and ensure they are addressed before they escalate. These developments align with broader labor rights trends and aim to improve retention and morale in a workforce that often faces high turnover.

State regulators are also focusing on audits and inspections, making it clear that safety compliance involves ongoing attention rather than once-a-year check-ins. This evolving approach means that cultivation facilities must embed safety into their daily management rather than treat it as a checkbox exercise.

Challenges and real-world impacts on growers and workers

For many cultivation facilities, adapting to new worker safety requirements is complex. Facilities face the twin pressures of maintaining production goals while also meeting safety demands that sometimes feel like an additional operational burden. Smaller and newer operations in particular wrestle with costs related to upgrading infrastructure and retraining staff.

Still, these changes bring long-term benefits, as safer facilities reduce absenteeism and improve the overall quality of work life. Some experienced growers see this as part of cannabis cultivation maturing into a serious, professional industry worthy of investment and respect.

The ripple effects extend beyond the workplace, too. Customers and regulators increasingly look for facilities that demonstrate commitment to safety and ethical work practices, creating market advantages for those who take these regulations seriously.

While it is too early to see consistent outcomes industry-wide, the move toward stronger worker safety regulations signals a welcome commitment to balancing productivity with human considerations. It hints at a cannabis industry that no longer sees its workforce as just a means to an end but as a vital component of sustainable growth.

For those interested in following these developments, resources like the California Division of Occupational Safety and Health cannabis safety page and OSHA’s cannabis safety guidelines provide detailed, state-specific insights and practical advice. Meanwhile, broader labor insights from California Labor & Workforce Development Agency give useful context on evolving worker protections. These sources offer a valuable starting point for facilities and employees alike to understand their rights and responsibilities in this shifting landscape.

As cannabis cultivation facilities continue to navigate this evolving regulatory environment, it’s clear that worker safety is moving from an afterthought to a core pillar of good operations. The ways these rules shape cultivation will be important to watch as they affect everything from plant handling to overall workplace culture.

Looking ahead from a grounded perspective

What stands out is that these evolving regulations reflect broader patterns common across emerging industries. They respond to growing pains and the need to protect people who often bear early risks. Cannabis cultivation, once operating in legal gray areas, now faces the responsibility to show that worker health cannot be compromised for the sake of production.

This shift involves some discomfort and adjustment but also an opportunity for the industry to evolve responsibly and sustainably. As safety practices normalize, both workers and operators can benefit from healthier conditions and a more resilient workforce. Ultimately, the hope is the cannabis cultivation workplace becomes a space where care for plants goes hand in hand with care for people.

What comes next may well depend on how regulations continue to balance industry growth with human factors, a subtle but vital challenge shaping cannabis’s ongoing transformation.

For readers interested in deeper dives, trade groups like the National Association of Cannabis Businesses also provide valuable updates on regulatory shifts and best practices in workplace safety.

This growing body of practices and policies ultimately offers a window into how cannabis cultivation is not merely about production but about cultivating a work environment that reflects maturity and respect for everyone involved.

Sources and Helpful Links

- California Division of Occupational Safety and Health – Official guidance on cannabis worker safety regulations in California

- OSHA Cannabis Safety Guidelines – Federal perspectives on workplace safety within cannabis cultivation

- California Labor & Workforce Development Agency – Information on worker rights and protections

- National Association of Cannabis Businesses – Industry updates and best practices including safety protocols