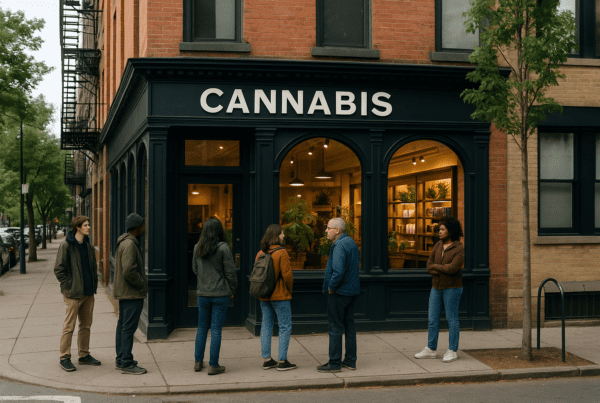

Recent moves by several states to introduce or tighten biosecurity requirements for cannabis cultivation signal a shift in how the industry manages plant health and operational hygiene. These policies come with good intentions, aiming to curb the spread of pests, pathogens, and contamination risks that could imperil crops and the supply chain. Yet for cultivators, adapting to these new rules often feels like moving target challenges layered on top of an already complex growing environment.

Growing Anxiety Around Pest and Disease Control

Biosecurity efforts are fundamentally designed to prevent outbreaks of pests and diseases across cultivation sites. That goal rings true within the cannabis space, where infestations can quickly spread and impact entire rooms or warehouses, not to mention the downstream effects on product safety and market access. State regulators push for standardized measures, such as controlled entry points, sanitation protocols, and sometimes mandated monitoring or reporting of pest outbreaks.

While the logic makes sense in a broad sense, cultivators are reporting difficulties in meeting these expectations without compromising other aspects of their operations. For example, enforcing strict visitor controls and facility access can interfere with workflow or quick response during critical cultivation phases. Small legacy farms often lack the infrastructure to fully isolate growing areas, complicating compliance further.

The Balancing Act Between Biosecurity and Environmental Control

Environmental cycling is a delicate element in cannabis cultivation. Adjusting airflow, humidity, and temperature often means opening doors, venting spaces, or moving equipment-actions that might run counter to rigid biosecurity measures requiring sealed environments and dedicated entry zones. Growers find themselves balancing two priorities that can sometimes feel contradictory: maintaining an ideal microclimate for plants while locking down pathways that might carry contaminants.

This tension reveals itself in choices about personnel practices, too. Some states demand use of personal protective equipment, changing clothes when moving between rooms, or even footbaths to disinfect footwear. To a grower, these add layers of complexity and time burdens, yet they are accepted as part of hardening facility hygiene. The cost in labor or reduced agility during crop stages remains a concern, especially in more labor-intensive setups.

Challenges in Reporting and Record-Keeping

With biosecurity regulations often come stricter requirements to document activities such as pest detections, sanitation routines, and supply chain inputs. This paperwork can grow burdensome, particularly for cultivators who once operated with minimal oversight or informal tracking methods. Digital record systems help bridge this gap, but they require investment and training.

There is also worry about how transparent reporting might expose vulnerabilities or increase liability. Growers worry about whether honest communication regarding pest occurrences could lead to penalties or unwanted scrutiny, making some cautious about documenting every detail perfectly. This creates an uneasy dynamic where compliance and trust do not always align comfortably within operations.

Infrastructure and Cost Implications

Implementing biosecurity measures often leads cultivators to modify facilities-installing quarantine rooms, upgrading HVAC and filtration systems, and creating dedicated clean zones. These upgrades are hardly trivial. Alongside initial capital costs, there are ongoing expenses like maintenance, monitoring, and training, which can significantly impact small and medium-sized businesses.

For many cultivators, these costs weigh heavily against thin margins that characterize legal cannabis markets. Some growers find themselves navigating grant programs, cooperative models, or scaling strategies just to meet regulatory expectations while staying afloat. Observers note this challenge could reshape local cultivation landscapes, especially in regions with patchwork enforcement.

Fragmented Regulations Adding Complexity

The cannabis sector remains a patchwork of overlapping state, local, and sometimes tribal regulations. This fragmentation means growers operating near borders or across jurisdictions confront differing standards for biosecurity. One farm might have to follow a strict decontamination protocol while a neighbor a few miles away has no such obligation.

This lack of regulatory harmony frustrates industry participants attempting to adopt best practices consistently. While some industry groups and consultants offer guidance, growers must often parse evolving rules from multiple agencies, a task demanding time and expertise that detracts from core cultivation efforts.

Finding Practical Paths Forward

Despite frustrations, many cultivators see value in the biosecurity push, recognizing that protecting crops from pests and diseases is essential for long-term viability and consumer confidence. Success stories often involve growers integrating biosecurity into their operational routines in manageable, incremental ways.

Such adaptation leans on leveraging trusted suppliers, developing in-house monitoring expertise, and fostering communication within grow teams. Technology adoption around data capture and environmental sensing also shows promise in minimizing guesswork and spotting early signs of trouble.

Ultimately, the advent of biosecurity requirements in cannabis cultivation mirrors broader agricultural trends emphasizing risk management and quality assurance. The hurdles facing growers today underscore a transitional phase as an industry matures amid evolving regulations, market pressures, and ongoing biological challenges.

For those keen on following these developments or seeking guidance, resources like the USDA Plant Health Programs and state-level agricultural extensions can offer relevant insights. Trade publications and consultants specializing in cannabis also often publish updated reviews of biosecurity protocols and practical strategies.

As the cannabis sector grapples with these new biosecurity frameworks, the story is far from settled. Cultivators will continue negotiating the practical realities, costs, and benefits, sculpting a future where plant health is a recognized priority balanced against the realities of growing a complex crop under regulatory lights.

Beyond policy and compliance, these challenges invite a deeper appreciation for the intricate biological and logistical dance beneath every legal cannabis product, a reminder that cultivation remains a craft shaped by nature, science, and evolving human systems.

Sources and Helpful Links

- USDA Plant Health Programs – Information about national plant health and quarantine regulations impacting agriculture and related industries.

- Penn State Extension on Cannabis Pest Management – Practical guidance on identifying and managing pests in cannabis cultivation.

- Colorado Cannabis Enforcement Guide – Details on current state regulatory requirements for cannabis operators, including facility and compliance standards.