New York’s cannabis industry is growing steadily, with expectations that it will play a significant role in the state economy. Yet behind the scenes, something less visible is altering the environment for growers and suppliers. Import tariffs on various types of equipment used in cannabis cultivation and processing are quietly reshaping costs and supply chain flows. The effects are subtle but steadily influencing how operators approach setup and expansion.

Hidden Toll on Grow Rooms and Gear

Equipment for cannabis cultivation is often specialized and sourced globally. Environmental control systems, lighting rigs, ventilation units, and extraction machines frequently come from manufacturers outside the United States. These import tariffs, which increase the costs of foreign products, put pressure on businesses. It is not just a simple higher sticker price; the tariffs tighten decisions about investment and timing.

For cultivators setting up indoor grow rooms, essential items like LED grow lights or climate controllers sometimes face tariffs depending on their country of origin and type. It can make certain popular models substantially more expensive, pushing operators towards less tested alternatives or older generation equipment. Lighter capital investment might lead to compromises in efficiency, plant health, or energy use.

These tariffs were initially part of broader trade policies aimed at balancing commerce but have found an unexpected foothold in cannabis cultivation equipment. The cannabis sector, newly legalized in New York, is keenly vulnerable to these cost changes especially in these first few years when business models are still evolving.

The Supply Chain’s Ripple Effects

Suppliers of cannabis equipment often navigate complex international networks. Many components are assembled across several countries where tariff structures differ. When a shipment hits New York, tariffs layered on at customs can disrupt pricing strategies and inventory turnover.

This has caused some distributors and retailers to reassess their stock levels and sourcing routes. There is a growing trend toward seeking domestic alternatives where possible or even encouraging manufacturers to shift production to the U.S. in order to avoid tariffs. However, domestic alternatives may not yet match the performance or price point that operators are accustomed to.

Growers might feel this impact indirectly as prices rise or availability narrows. In some cases, supply delays caused by tariff-related paperwork and customs inspections extend lead times and stress planning. This adds up to an economic environment where careful budgeting becomes more crucial.

New York’s Market and Broader Implications

New York’s cannabis market is still finding its footing, trying to balance ambitious social goals with practical business realities. The higher cost of equipment caused by tariffs hints at larger challenges for equity-focused growers who may already face capital constraints.

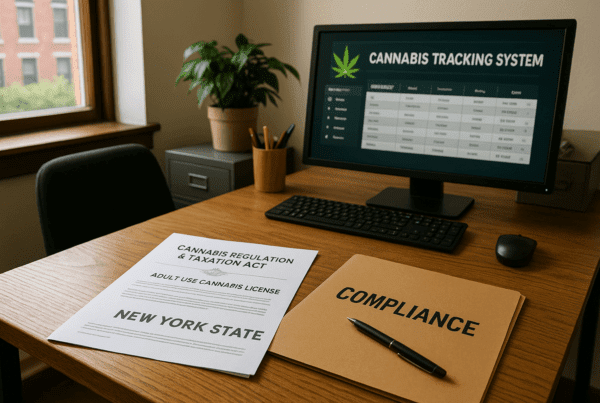

Startups and small-scale cultivators could find themselves squeezed between rising costs and regulatory requirements demanding precise equipment for compliance and quality control. This creates a form of invisible pressure stretching beyond the obvious factors like licensing fees or taxation.

There may also be incentives at play, as New York officials consider programs to boost local manufacturing of cannabis supplies or reduce barriers. Some advocate for revisiting tariff policies on cannabis-specific equipment or related components to encourage market growth and innovation.

Meanwhile, the evolving international trade landscape means this influence on cannabis cultivation is not static. Changes in trade agreements, political priorities, or economic conditions could shift the costs again, requiring ongoing adaptation by those invested in the New York cannabis ecosystem.

A Closer Look at What’s Affected

Diving deeper, some specific categories of cannabis equipment are notably impacted by import tariffs. These include high-tech lighting solutions, such as full spectrum LED panels favored for their energy efficiency and plant benefits. Many come from manufacturers in Asia or Europe, and tariffs can raise prices by a noticeable margin.

Other equipment includes extraction machinery used to process cannabis into concentrates and oils. These are often complex devices with specialized parts sourced globally. Tariffs on these items mean processors face higher upfront costs, and consumers might eventually see the effect on product pricing.

Even simpler tools, like certain types of ventilation or filtration units, might carry tariff burdens if they originate from countries affected by current trade policies. The range of products caught under this umbrella shows the intricate link between global trade and local market realities.

A report from Colorado Oil and Gas Conservation Commission highlights how similar markets experience cascading cost pressures when tariffs ripple through supply chains. While Colorado differs from New York in its regulatory environment, the comparison illustrates potential trends.

Looking Toward Solutions and Adaptation

Plant operators and industry stakeholders are not standing still. Some are closely monitoring tariff changes and exploring new supplier relationships. Others invest time in local partnerships or advocate for policy adjustments that might soften tariff impacts. The domestic manufacturing scene for cannabis equipment, though still emerging, offers hopeful possibilities for long-term solutions.

Organizations focused on cannabis business development in New York have begun workshops and informational sessions to help cultivators navigate these economic nuances. There is a growing recognition that import tariffs, while somewhat removed from everyday plant care, are shaping the economic landscape of cannabis cultivation.

Understanding these subtle shifts helps growers and industry participants plan with more awareness rather than reacting to surprises. As the New York cannabis market matures, the relationship between trade policy and operational costs remains a factor quietly guiding evolution.

For those watching this story unfold, staying informed about trade policies, tariff changes, and their local impact will remain an important piece of the broader cannabis business puzzle. More than a background detail, these economic elements connect global commerce to the cultures of growing and consuming cannabis right here in New York.

For more insight into how tariffs affect equipment pricing and sourcing strategies within the regulated cannabis sector, the National Cannabis Industry Association provides ongoing updates on policy and industry responses (NCIA).

Meanwhile, New York’s official cannabis regulatory site offers information relevant for growers and operators navigating costs and compliance (New York State Cannabis Control Board).

As these dynamics unfold, the industry’s interplay with broader economic factors keeps evolving, quietly shaping the path forward.

Sources and Helpful Links

- New York State Cannabis Control Board, official state cannabis regulatory information and updates

- National Cannabis Industry Association, a hub for cannabis business policy news and advocacy

- Colorado Oil and Gas Conservation Commission, example of related market impact research on equipment and tariffs