It is becoming increasingly clear that the landscape for indoor cannabis cultivation is being influenced by more than just genetics and market demand. Behind the scenes, changes in state energy policies are nudging growers to reconsider how they power their operations. These shifts are part of larger conversations about energy sustainability, grid reliability, and environmental impact, which are proving difficult to separate from the hands-on realities of cannabis cultivation.

When Energy Costs and Regulations Meet the Grow Room

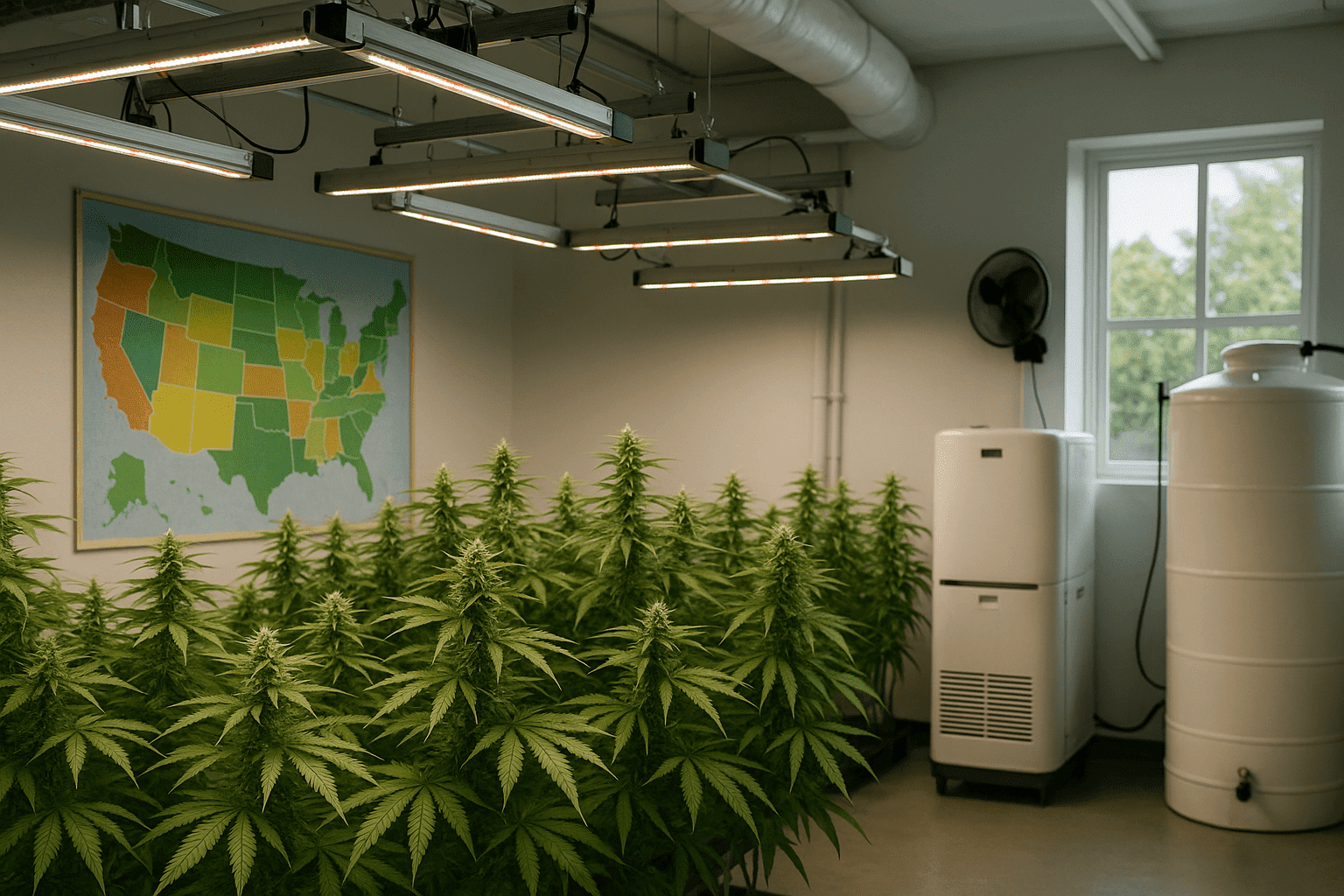

Indoor cannabis cultivation has long been known for its significant energy consumption. The intense lighting, climate control systems, ventilation, and dehumidification required place these operations among the most energy-intensive agricultural setups. Historically, many states took a hands-off approach toward the environmental footprint of such facilities. However, as cannabis legalization brings the industry into clearer regulatory sight, energy policies are evolving accordingly.

In states like California, Oregon, and Massachusetts, new energy rules have introduced tighter efficiency standards and incentives for growers to adopt less power-hungry technologies. These policies aim to curb peak demand loads that indoor grows contribute to the local electrical grid, especially during summer months when longer daylight hours encourage longer grow cycles. For cultivators, this means evaluating their lighting setups far beyond just plant productivity-energy consumption now carries real financial and compliance stakes.

The push toward LED lighting from high-pressure sodium or metal halide lamps is a clear example. LEDs typically use less energy per unit of light produced and generate less heat, relieving cooling loads that otherwise hike up electricity bills. But upgrading involves upfront costs and learning curves, especially for smaller-scale cultivators who might hesitate to overhaul systems that worked well enough before policy-driven pressures.

Strategies Growers Employ in Response to Incentives and Limits

Energy efficiency is no longer optional in many places. Some states have begun offering rebates or tax incentives to growers who install energy-efficient HVAC systems or smart controls that can modulate climate zones more precisely. For example, Nevada’s programs encourage greenhouse hybrids that can leverage natural light while continuing some indoor controls, creating a balance between regulation and production goals.

This trend reveals an emerging mindset among indoor cultivators, who increasingly see operation expenses tangled with regulatory risk. Unlike past years, where growers might have prioritized yield at almost any cost, the calculations now include considerations like kilowatt-hour caps, anticipated penalties, and mandatory reporting on energy use.

There are also collaborative efforts where cultivation facilities partner with utility companies to monitor real-time usage, shift non-essential power consumption to off-peak periods, or even participate in demand response programs. These programs pay growers to reduce loads when the grid faces heavy stress, sometimes requiring temporary dimming or shutting off of lights and equipment.

The Environmental Side of Cannabis Cultivation Choices

The energy policy changes ripple beyond immediate cost concerns into how the cannabis industry is perceived environmentally. As part of a broader social push for sustainability, some cultivators are embracing renewable energy sources. Solar panels atop warehouses and battery storage systems help offset reliance on fossil-fuel-powered electricity, though the expenses and complexities can be significant.

Meanwhile, environmental certification programs are beginning to include energy footprint assessments as part of their auditing processes. These certifications can attract customers who want to support environmentally responsible cannabis brands, further incentivizing growers to rethink energy use. However, this comes with the challenge of balancing local climate conditions, strain requirements, and production timelines with sustainability goals.

In certain regions with aggressive clean energy mandates, cultivators face the choice of redesigning their entire HVAC and lighting infrastructure or relocating to facilities better suited to compliance. This dynamic illuminates the tension between expanding commercial needs and evolving environmental policies that aim to curb carbon footprints.

Looking Ahead – A Patchwork of Decisions Influenced by Local Policies

The reality across the U.S is a patchwork of differing state energy rules, financial incentives, and enforcement priorities that shape how indoor cannabis grows operate. In states with no clear mandates, traditional high-energy practices continue with little immediate pressure. Elsewhere, aggressive state programs are pushing the industry toward efficiency and technological innovation faster than some might have expected.

This variation means that cultivators must stay abreast of their state’s regulatory environment, not only for licensing and cultivation rules but for energy policy shifts that can affect operational viability. It also encourages a gradual industry evolution where energy-related decisions, from equipment choice to facility design, can determine competitive advantage as costs and compliance risks weigh on the bottom line.

The interaction between energy policies and cannabis cultivation is an unfolding story, reflecting broader conversations about agriculture’s role in sustainability and how emerging industries adapt to evolving societal expectations. The growers who move thoughtfully in this context may find not only cost savings but opportunities to lead in a market increasingly attentive to environmental impacts.

- California Energy Commission, detailing energy efficiency programs for cannabis cultivation California Energy Commission Cannabis Energy Programs

- Oregon Department of Energy guidance on energy conservation measures affecting cannabis Oregon Energy Cannabis Conservation

- Massachusetts Clean Energy Center resources supporting indoor grow energy upgrades Massachusetts Indoor Cannabis Energy Efficiency

- U.S. Department of Energy’s overview on energy use in agriculture, including controlled-environment agriculture DOE Energy Use in Agriculture

Sources and Helpful Links

- California Energy Commission Cannabis Energy Programs – Details energy efficiency requirements and incentives aimed at indoor cannabis cultivation in California

- Oregon Energy Cannabis Conservation – Guidance on energy saving measures for cannabis growers within Oregon’s regulatory framework

- Massachusetts Indoor Cannabis Energy Efficiency – Resources and programs encouraging energy upgrades for indoor cannabis cultivation

- DOE Energy Use in Agriculture – Overview of energy consumption patterns in agriculture, including controlled-environment agriculture